Galvanizing Iron

Galvanizing is a process used to apply a protective zinc coating to steel or iron to prevent rusting. There are two main methods for galvanizing steel. One is Hot Dip Galvanizing and the second method is Electro galvanizing. We prefer Hot dip galvanizing. You can find the procedure hereunder.

- Hot Dip Galvanizing

Hot-dip galvanizing is a process that involves immersing steel or iron into molten zinc, creating a protective layer to prevent corrosion. This metallurgical bond ensures durability, corrosion resistance, and longevity, making it a widely used method for safeguarding metal structures and components in various industries.

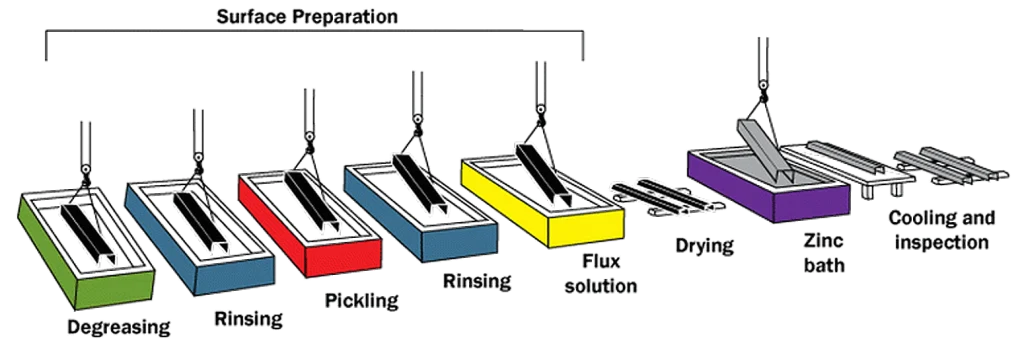

Surface Preparation

The steel is first cleaned to remove any rust, oil, or mill scale. This is typically done through a process called pickling, where the steel is immersed in a solution of acid. Fluxing: After cleaning, the steel is fluxed to remove any

Fluxing

After cleaning, the steel is fluxed to remove any remaining oxides and to promote the bonding of the zinc coating. Fluxing is usually done by dipping the steel into a flux solution or by applying a powdered flux.

Galvanizing Bath

The cleaned and fluxed steel is then immersed in a bath of molten zinc at temperatures typically around 450°C (850°F). The zinc reacts with the surface of the steel to form a series of zinc-iron alloy layers.

Quenching

After immersion, the steel is withdrawn from the zinc bath and allowed to cool. This can be done by air cooling or quenching in water.

Importance of Galvanizing Iron

Corrosion Protection

The primary purpose of galvanizing steel is to protect it from corrosion. The zinc coating acts as a physical barrier between the steel and the surrounding environment, preventing rust and corrosion.

Durability

Galvanized steel is known for its long-lasting durability. It can withstand exposure to harsh weather conditions, extreme temperatures, and other environmental factors without degrading.

Cost-Effective

While the initial cost of galvanizing might be higher than some other coating methods, the long-term cost benefits are significant. Galvanized steel requires minimal maintenance and offers a longer lifespan, reducing the need for frequent replacements.

Characteristics of Galvanized Steel

Appearance

Galvanized steel has a distinctive matte gray or spangled appearance, depending on the specific galvanizing process.

Zinc Alloy Layers

The zinc coating on galvanized steel typically consists of multiple layers of zinc-iron alloy. This provides enhanced adhesion and corrosion resistance.

Galvanic Protection

The zinc coating acts as a sacrificial anode. In the presence of moisture, zinc corrodes preferentially to steel, protecting the underlying steel from rust.